Advantages of 3D Printing

Due to its ability to utilize only the necessary material and eliminate the need for tooling, 3D printing emerges as a highly cost-effective manufacturing method for producing one-off parts or small batch productions.

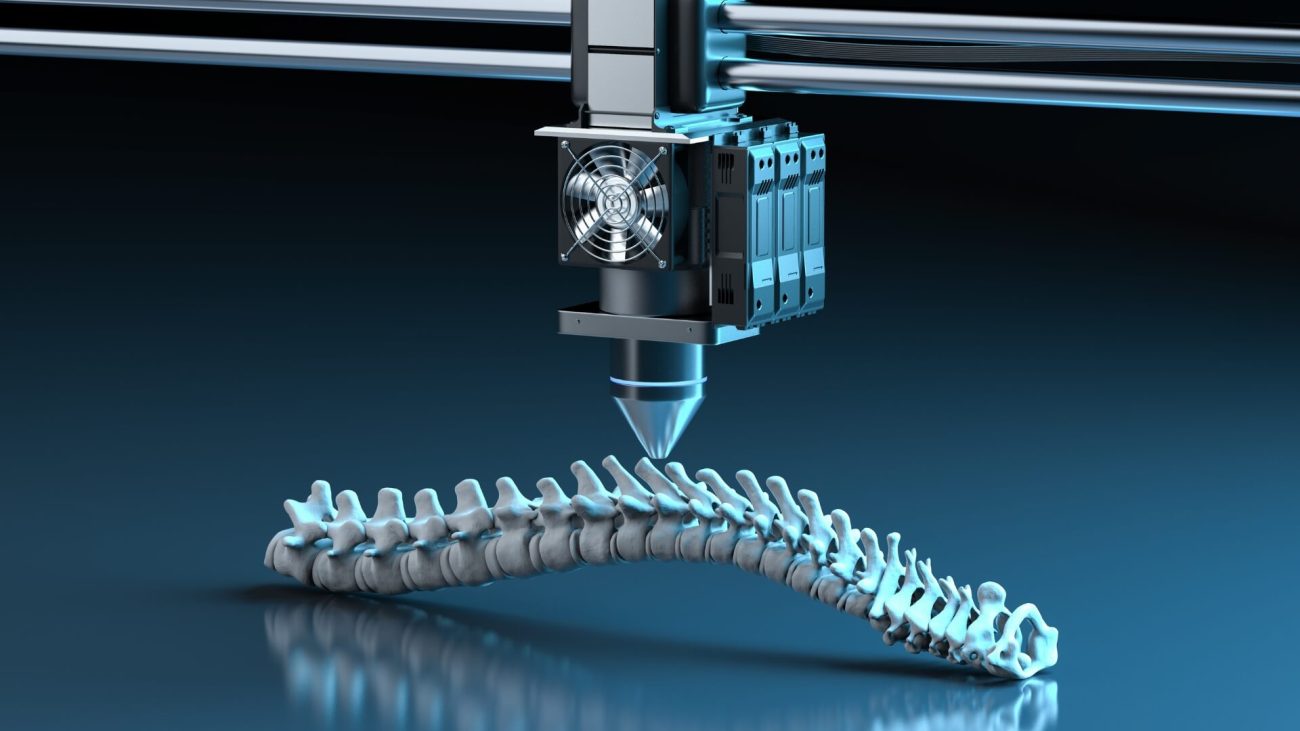

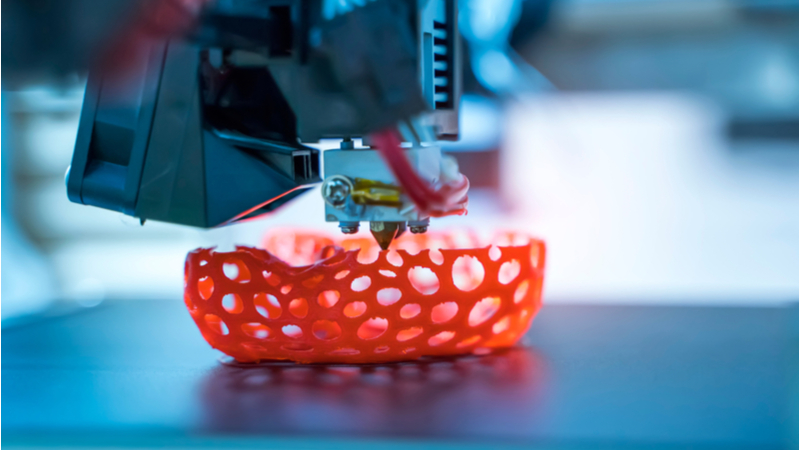

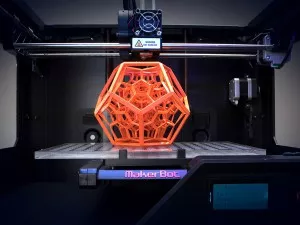

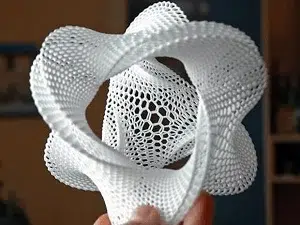

Robust 3D printers fabricate components by depositing layers of material under the precise control of a computer-controlled nozzle. This advanced technology enables the production of intricate shapes, including intricate interior geometries.

Upon completion of the part design using CAD software, the 3D printing process allows for rapid production within a few hours, eliminating the need for time-consuming setup procedures.

As 3D printed parts do not rely on tooling, the production process carries lower risk. In the event of a defect being identified post-printing, it can be digitally rectified without the need to replace costly tooling.

While 3D printers do require power to function, they typically generate minimal material waste. In contrast, subtractive processes such as machining result in the production of excess material waste.